Stefan Mordue, Architect and NBS Business Solutions Consultant, looks what levels of information are required at various stages of the BIM project lifecycle.

When you think of a model, perhaps the first thing that comes to mind is geometry. This is not surprising as models have been used for centuries to set out a designer’s intentions – conveying shape, space and dimensions. The ‘Great Model’ of Sir Christopher Wren’s St Paul’s Cathedral did this in the 1670s and can still be seen today.

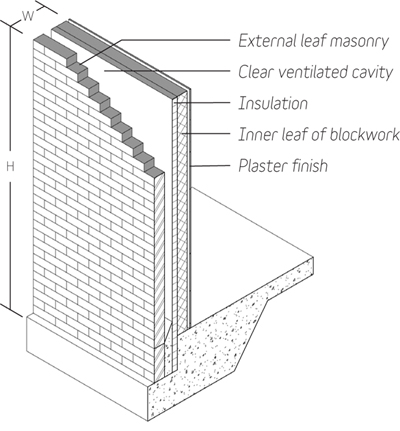

However, while the geometrical or graphical data can tell us the width of a brickwork leaf and the height of the walls, at a certain point during construction it is the written word that is needed to take us to a deeper level of information. It is within this textual environment that we describe the characteristics of the brickwork itself such as density, strength and source, and it is words that are used to describe the kind and type of mortar joint and wall ties.

In the context of BIM, we are actually looking at a rich information model which, aside from graphical data − such as geometry and shape − also includes non-graphical information such as performance requirements and associated documentation, presented in a specification or manual format. The written specification is not new and has been around for centuries. However, it is only now by combining these aspects of graphical and non-graphical information that we get the ‘overall picture’.

Today, clients are not only procuring a physical asset: they are also procuring information, typically in a digital format. The amount and level of information increases as we progress through the project lifecycle. For example, at an early strategic briefing stage, when the client is assessing needs, there may just be a requirement for spaces and activities. At concept stage this will be developed into the design intent of elements/systems to meet the Employer’s Information Requirements (EIR). This is then further developed at design stage when considering the characteristics of each deliverable in terms of performance requirements; this could relate to security requirements of a plant room space, an external wall element or a doorset system. At technical design stage, or at least prior to construction, product selection can be determined by the specifier or delegated as ‘contractor’s choice’ based upon generic product performance requirements.

The Government’s ‘Soft Landings’ guidance recommends that a building’s ’in operation’ phase should be considered throughout the whole project lifecycle. By establishing required performance outcomes and operational budget at an early stage, these can then be compared to the actual performance outcomes. From a concept stage, the performance criteria − such as the structural performance of a partition system − can be considered. As the information develops, specific references to relevant standards and classes are stated, along with any testing methods that may be required. Certifications by accredited third party certification bodies are also considered as the information progresses, to ensure that the client’s outcomes are met at the end of the project. At project handover, information specific to the installed object’s operation and maintenance is incorporated into standard COBie properties, as well as documentation such as links to PDF manuals.

Example: Partition system

| Banding code |

Description | Example |

|

What is typical for concept stage? |

A simple description outlining design intent. |

Partition system |

|

What is typical as the design develops? |

The specified overall performance of the deliverable. |

Partition system |

|

What is typical in technical design? |

The prescribed generic products that meet the desired overall performance requirements. |

Partition system |

|

What is typical in the construction phase? |

The prescribed manufacturer products that meet the generic product specification. |

Partition system |

|

What is typical for operation and maintenance? |

The key properties to be transferred into an asset database. |

Partition system |

Example: Surveillance systems

|

Banding code |

Description |

Example |

|

What is typical for concept stage? |

A simple description outlining design intent. |

Surveillance systems |

|

What is typical as the design develops? |

The specified overall performance of the deliverable. |

Surveillance systems |

|

What is typical in technical design? |

The prescribed generic products that meet the desired overall performance requirements. |

Surveillance systems |

|

What is typical in the construction phase? |

The prescribed manufacturer products that meet the generic product specification. |

Surveillance systems |

|

What is typical for operation and maintenance? |

The key properties to be transferred into an asset database. |

Surveillance systems |

Example: Typical masonry construction detail - some of the graphical and non-graphical considerations

Non-graphical information

Performance

– Accuracy tolerances (for structural performance)

– Design submittals requirements (applicable where there is a contractor-designed component)

– Working life

– Fire performance

– Structural performance – impact, M&E services, vehicular

– Heat loss (U value)

Execution

– Workmanship during adverse weather

– Cleanliness

– Reference and sample panel requirements (to monitor workmanship, materials quality)

– Specific product installation requirements (e.g. installing cavity wall insulation, installing lintels, block bonding new walls to existing, laying frogged bricks in mortar)

Product properties

– Thermal conductivity

– Freeze/Thaw resistance

– Recycled content

– Dimensional tolerances for masonry units

– Compressive strength

This article originally appeared in the NBS National BIM Report 2015. Download your free copy of the full report containing specialist insight and analysis.

Related NBS Services

Develop specification information through the construction timeline with NBS Create. Our software allows you to create outline specifications, considering performance throughout, and then develop this through to a full specification.

The NBS BIM Toolkit allows collaborative project teams to define how much information is required and when it should be provided through the project timeline.

Create your first NBS BIM Toolkit project ![]() .

.