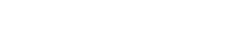

With its unique interlocking tube design and potential to build an infinite number of structures, it’s no wonder that the humble LEGO brick has stood the test of time. The original patent was signed at the end of January 1958 by Godtfred Kirk Christiansen, and each of the 19 billion bricks produced this year will snap perfectly onto those made sixty years ago.

The history of LEGO

LEGO was named the world’s most powerful brand in 2015 and has a long history of encouraging creativity and innovation among children. The bricks were marketed in 1960 as ‘a new concept in educational play’ and in the years that followed have been used in the classroom and even the office as well as at home.

The brand has evolved to include buildable sets including characters and scenes from Star Wars, Disney, DC Comics and Minecraft.

Manufacturing

LEGO pieces are made using a plastic called acrylonitrile butadiene styrene (ABS). As of September 2008, LEGO engineers use the Siemens NX software suite to model the elements – this allows the parts to be optimized by way of mould flow and stress analysis.

Surely LEGO bricks aren’t a suitable building material?

Definitely not for life-sized projects, but the world’s favourite toy has inspired a great deal of discussion within the construction industry.

In 2011, the Dutch professor Hennes de Ridder coined the term ‘legolisation’, which makes the case for certain structures being made from elements that are the same in dimensions, interface and function.

The benefits of ‘legolisation’

- Faster construction

- Lower building costs

- Lower costs of failure

- Materials can be reused

- Opportunities for design are still endless

The Israeli company ‘Kite Bricks’ has been working on what they call a ‘smart brick’, a highly resistant concrete brick which locks easily into another, meaning we really could be using the construction equivalent of a LEGO brick in the future. However, it’s worth noting that these bricks first hit the news in 2014 and we’re yet to see them adopted or even patented.

Building with BoKlok

While smart bricks may not be in our immediate future, some manufacturers have successfully adopted a LEGO-style approach to building and design. BoKlok, for example, is a collaboration between IKEA founder Ingvar Kamprad and Skansa’s chairman Melker Schorling and creates what they call ‘affordable homes for ordinary people’. Their buildings are efficiently and sustainably made, making maximum possible use of minimal space, and can be found in over 100 developments across Sweden.

Lessons we can learn from LEGO

There’s a lot that the construction industry can learn from how LEGO operates as a company as well as what it produces.

Sustainability: In 2015 LEGO opened its own Sustainable Materials Centre, hiring over 100 new employees and investing over 135 million euros in finding sustainable materials to build their bricks from as well as their packaging.

Creativity: We may not be ready for smart bricks just yet, but we can nonetheless take a leaf out of LEGO’s book when designing our buildings. Rather than creating rigid elements, unique to the point that they are unusable in any other form, why don’t we futureproof construction by using materials and structures that can be used to make, maintain and remake buildings?

Play: LEGO’s ‘Serious Play’ scheme has highlighted the benefits playfulness and fun can have in a working environment. Whether it’s to work through emotions or to literally build the very first model of your next project, LEGO bricks are an old staple that can be used extremely innovatively.

Perhaps every office should have a bucket of the stuff.