BIM for Health and Safety

The 2012 Association for Project Safety (APS) convention held in Newcastle, entitled, 'The Changing face of construction', focused on Building Information Modelling (BIM) and how a CDM Co-ordinator (CDM-C) should be interacting with design and construction teams on BIM projects. With BIM very much the buzz word, Stefan Mordue, Architect, Registered CDM-C and technical author for the NBS, gives his thoughts on what BIM means for health and safety and the CDM-C.

Been there, seen that, got the T-Shirt

Ever since the landmark reports from Latham (Constructing the team) in 1994 and Eagan (Rethinking construction) in 1998, the construction Industry has striven for improved productivity, efficiency and cost savings. The 'Government Construction Strategy', published in 2011, continues these themes and adds collaboration.

This latest strategy paper outlines the Government's plans to reduce government construction project costs by 15 to 20%. These are not arbitrary figures, 20% savings have been measured, recorded and published following work carried out by the BRE in the 1970s and 80s, and again they are highlighted by Egan and Latham following studies of the UK construction industry in the mid-to-late 1990s.

Figure 1: Reoccurring themes

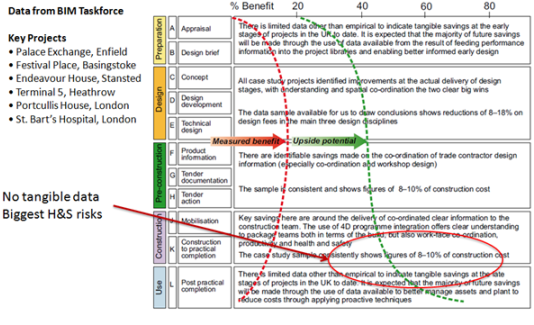

One recent efficiency innovation, Building Information Modelling (BIM) has demonstrated that it can achieve this level of cost savings and reduce the health and safety risk by improving the construction process. It is the Government's intention to require collaborative 3D BIM on all central government department projects by 2016. A minimum collaborative Level 2 BIM, i.e. COBie, is currently required as of this year. A number of government pilot schemes have been undertaken where early indications show that BIM's biggest benefits are in the construction and post occupancy phases. However, the use of BIM has yet to realise tangible health and safety data during the latter stages of the construction process, when most accidents occur.

Figure 2: Post construction benefits still to be realised

Image source: Investors Report - BIM Taskforce. Image: Adapted Mark Bew - IGO Global 2010.

Health and safety

There are many challenges facing the CDM-C in the context of methods of work. In October 2010, Lord Young's 'Common sense common safety' report was published as a response to the coalition governments pledge to review and reform health and safety legislation. This in turn led to the Government commissioning an independent and comprehensive review, led by Professor Lofstedt, of the UK's health and safety regulations. The outcome was 'Reclaiming health and safety for all'.

So what are the current challenges facing health and safety? The Coniac CDM 2007 Evaluation and the Red Tape Challenge have led the Health and Safety Executive to announce its intention to simplify and rationalise the CDM Regulatory Package, which is likely to lead to a CDM 2014. However, in the wider backdrop and context of the construction industry we are now entering the digital construction age.

Digital construction

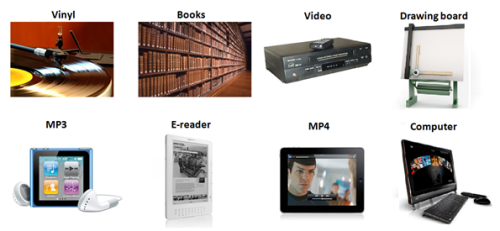

What is digital construction? BIM is often described as a software package but it is an approach that cannot be found in a box. It is a culmination of software, people and process, all of which is underpinned by information. We have seen a digital switch-over happening in many other industries. We only have to think of vinyl records, tapes and CDs being replaced by MP3 digital downloads; videos and DVDs being replaced by streaming from the internet, and books being replaced by the E-reader. In many cases, digital sales are outstripping traditional media.

Figure 3: The digital switch over

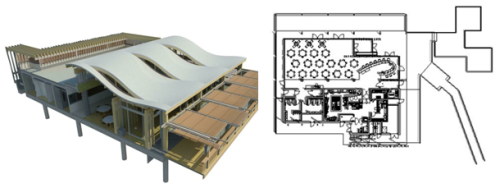

Figure 4: Digital construction

Now let us turn to the design process where we have seen the demise of the drawing board, giving way to the computer and graphics tablet. Today, buildings are being modelled rather than drawn; the implications are profound and will result in considerable changes in our approach.

Traditionally, 2D drawings were produced and viewed together to imply a 3D representation. Now, 2D drawings are an 'output' of a 3D model, they are relatively easily generated using computer graphics.

With BIM, design and construction documents can be produced more quicklyand more effective design decisions can be made at an earlier point in the design process. This means that we have greater opportunities for coordination, collaboration and production efficiencies.

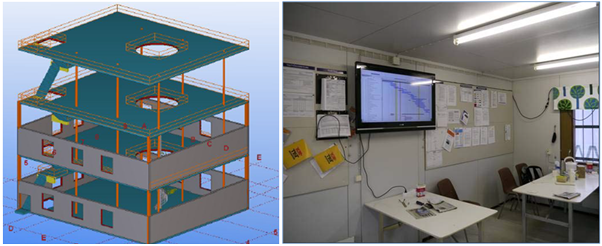

Figure 5: Buildings are modelled rather than drawn

Hollywood fantasy?

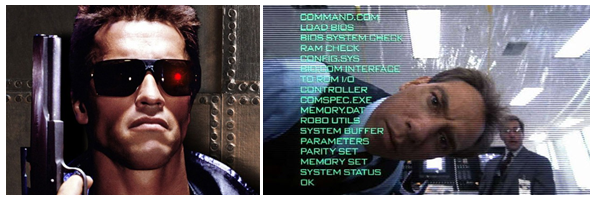

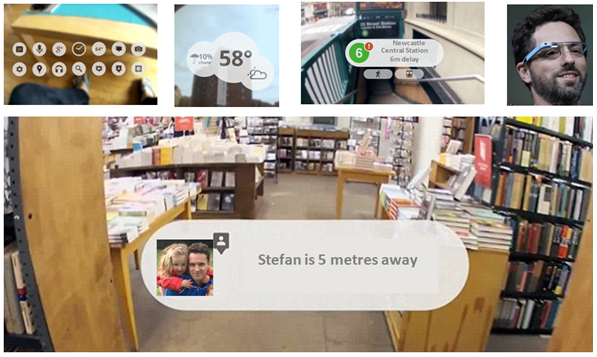

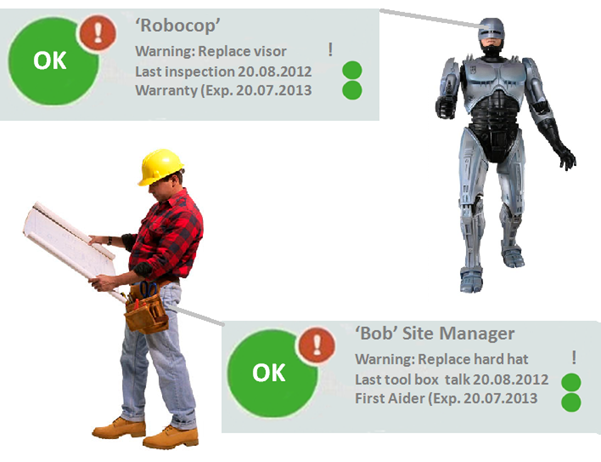

Classic films such as Robocop and Terminator, produced as early as the 1980's, envisaged the use of augmented reality (AR) where digital data is overlaid on the real world. In the 2002 film 'Minority Report', starring Tom Cruise, we see people walking past advertising billboards and getting personalised adverts. This may all seem like Hollywood fantasy but the reality is that this technology is available and being utilized by many other industries. It may be hard to think of these technologies in a construction context, but imagine their application on a construction site. By linking data bases we can begin to see when an operative last had a tool box talk, when their hard hat is about to expire and should be replaced, and what qualifications they hold. This is information that is readily available (perhaps currently in several places), the technology exists to use it, so perhaps this 'fantasy' is not so farfetched?

Figure 6: Early films envisaged augmented reality (AR)

Image Source: Orion Pictures

Figure 7: Technology is here today

Image source: Google, Adapted Stefan Mordue

Figure 8: Technology in a construction context

Image source: Adapted Stefan Mordue

Opportunities

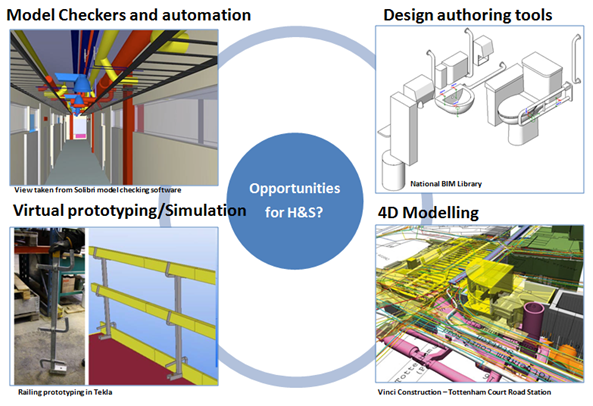

BIM has brought about a number of opportunities for health and safety in a number of areas:

Figure 9: BIM opportunities for H&S

Image source: Solibri, NBS, Tekla, Vinci Construction, Adapted Stefan Mordue

Model checkers and automation

The Singapore Corenet eplan check software has been around since 2001. It is Government funded and allows a design scheme to be checked for compliance against Building Regulations in as little as 30 minutes, using an internet gateway and an IFC file format. Other model checking software, such as Solibri, provides a way of checking a BIM for integrity, quality and physical safety, regardless of what BIM platform has been used to model it. Automation of checking is used for clash detection, fire exits and American Disability Act requirements. In one such research project, by using a number of rules, the software was able to detect the difference between an access hole and a service penetration, and install guard rails where appropriate. From this model, quantity take off was, performed, schedules updated and a visualisation created. However, while BIM can carry out compliance checking, it still needs human intervention and the setting up of 'rules'. The software can report on pretty much anything; however, it is up to a 'human' to decide what it is checking for.Design authoring tools

BIM objects, such as those in the National BIM Library, provide us with opportunities to include important COSHH data and hazards. BIM is as much about the embedded attributed data and information as the spaces and dimensional data that we represent graphically.The objects combine three sources of data:

- Industry Foundation Classes (IFC) parameters for interoperability between AEC software

- Construction Operation Building Information Exchange (COBie) - UK 2012 properties that have been defined by the UK Government's BIM Task Group

- National BIM Library properties as defined by our technical teams.

Aside from the physical dimensions of the objects themselves, we can also begin to consider further dimensions and zones, e.g. the minimum space requirements around plant, for access and maintenance.

Virtual prototyping and simulation

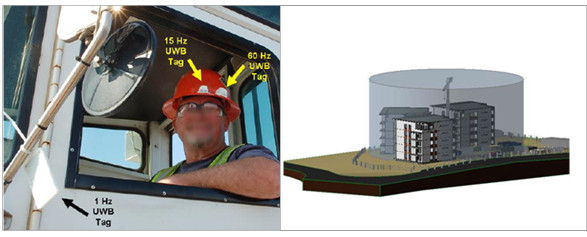

The key benefits of modelling allow us to present and simulate potential hazards, accident black spots and provide solutions in a completely (safe) virtual environment. We may think of clash detection in the typical sense of components, e.g. a pipe intersecting with a beam, usually all nicely colour coded, but how about clash detection with respect to activities, e.g. truck or crane movements on site? Through simulation, tagging and tracking we can begin to simulate safe material distribution and site traffic routes. One such research project which investigated real time, mobile tracking systems by placing a small tagging device on the workers hard hats and on the end on a crane, was able to establish safe proximity working zones throughout the site.4D simulation

4D simulations allow us to analyse time based aspects to assess building progress at any given point during the construction process. In one research project, the movements of a crane were modelled to establish how far across the site it would extend in order to establish lifting patterns, and the crash zone should it collapse. All done within the confines of the graphics card before any plant or personnel go on site.Communication

BIM is aiding communication on construction sites. For example, a number of trial projects have used LCD screens in welfare cabins to display essential current health and safety information and site visualisations indicating potential accident hot spots, with data taken directly from the model. However, while BIM allows us to work from multiple locations, it has also eroded our soft skills. The art of one to one communication is a skill that the CDM-C is perhaps best placed to undertake and should continue to embrace.

Figure 10: BIM is aiding communication on construction sites

Image sources: VTT, Georgia Institute of Technology, University of Colorado at Boulder

Change and adapt or be left behind

We can see that the fundamental principles behind BIM are simple and that there are key benefits in terms of productivity efficiency and reduced costs. However, we are only now beginning to see the implications of the use of BIM with respect to health and safety.

Do CDM-Cs need to be BIM experts? I would argue that you do not need knowledge in all technical aspects but must have an understanding of the fundamentals. PAS 1192-2:2012, which documents the delivery of BIM enabled information, is currently out for public consultation and is a document which CDM-Cs should become familiar with. A number of BIM enabling plans are being prepared such as the recently issued 'BIM overlay to the RIBA outline plan of work'. This lists the various players in the BIM process but fails to mention the role of the CDM-C coordinator, instead highlighting client representatives, technical advisers and delivery managers. Dr Terry Price of London Underground is currently leading comments on behalf of the APS and he has made it clear that in the BIM future it will no longer be just a question of roles, it will be more about responsibilities. He goes on to say that the CDM-Cs have to decide what roles they need to adopt in order to continue to give important advice in the management of health and safety during the construction process and over the whole life of the structure.

One thing is clear, however, the CDM-C will need to change roles or possibly be left behind. Consider this reason to change for a moment:

- In 1975 Kodak built one of the first digital cameras in collaboration with Apple

- The following year they had 90% of film and 85% of camera sales in the USA

- In 1996 this represented $16 billion revenue

- However, they failed to fully embrace digital technology and in 2012 Kodak filed for bankruptcy protection.