If the construction industry's attitude towards the environment today is compared with that of 25 years ago, it is apparent that modern practices have more empathy with natural materials. Industry professionals working on projects are seeking out innovative ways of minimizing environmental impact. Focus in achieving this is relevant to the four stages of a building's life: its design, construction, occupancy and demolition.

Technology is an important point of call when contemplating environmental impact. For example, during construction an insulation material's performance influences a building's heating demand; during occupancy use of renewable energy systems lessens the need for traditional mains supply. Recently, the industry has seen the resurgence of traditional construction materials. Timber is again an option for multi-storey framing, due to a number of beneficial factors like prefabrication quality, structural stability and sustainability credentials.

Earth is also a material that has made a comeback into modern construction. Monolithic rammed earth has been successfully used for the walls of the Eden Project entrance building in Cornwall. Unfired clay bricks (earth bricks) are other raw earth products that can be looked at in lieu of their energy intensive relatives. Moist earth (typically comprising of less clay than sand) is formed into a brick shape using one of three processes described below, prior to drying through a natural or unfired means:

- Moulding: Where the earth mixture has a high enough water content (up to 20%) to allow it to be poured into a brick-shaped mould.

- Extrusion: Where the earth mixture has a mid range water content (up to 14%) so that it is firm enough to retain its shape and also able to be forced through a die. The mixture is extruded as one long length and then a wire cutter divides it into individual bricks.

- Compression: Where the driest of the earth mixtures (a maximum water content of 10%) is subjected to relatively high pressures to produce dense individual bricks.

Historical use of earth bricks in the UK

As the materials needed to make earth bricks are literally under our feet, examples of their use in vernacular architecture can be seen globally. Around the UK, the technology has been identified by English Heritage in traditionally constructed cottages and farm buildings. In their 'Historic farmsteads' publications they describe the use of earth bricks in structures as beginning at the start of 18th century, but most examples belong to the mid 19th century.

During these centuries moulded earth bricks were used and referred to as clay lumps, clay batts or mud bricks. Surviving structures have been found in concentration in the East Anglia area, mainly in Suffolk and Norfolk. The use of earth bricks in these buildings would have gone undiscovered if not for the repair of their traditional lime or clay render systems with cement renders. These repairs affect the walls hydroscopic properties, gradually building up moisture and causing further render failures. When the exposed masonry is examined the earth brick core layers are revealed.

Early 19th century clay lump cottage, Buxhall, Suffolk

Studies of these buildings indicate that ingredients for the bricks consisted of clay, chalk, sand and gravel. Their manufacture used work animals to trample the mixture into a paste, which was placed into moulds prior to natural drying.

However, earth brick technology goes back further than the 18th century - there's evidence of its use during Britain's occupation by the Romans. During the 1982 excavation of the legionary fortress buildings in Colchester (Camulodunum), archaeologists unearthed intact wall stumps dating from the Pre-Boudican period (AD 47 to 60/61). Like the surviving structures in East Anglia, they follow the principle of building walls off plinths and providing a sacrificial layer of render. The walls were solid, approximately 430 mm thick, constructed off 300 mm high plinths, and protected with keyed daub render. Their exact height could not be determined as the fortress was destroyed by Boudica.

UK research into earth brick use and maintenance

Historic Scotland and Dr Paul Adderley from University of Sterling are carrying out scientific research into the maintenance of earth-based building products. They are using an evidence-based proactive approach (rather than an anecdotal and reactive approach) to this kind of conservation work. Documented on Historic Scotland's 'Technical Conservation' website are two major research techniques used: thin section micromorphology and luminescence dating. These will allow an earth wall's microscopic structural features, its temporal aspects and its rates of change to be established, to effectively prioritize conservation work.

lsewhere, the University of Bath in cooperation with the Building Research Establishment are testing this traditional material and its building techniques to establish its relevance in modern construction. The tests will determine not only an earth brick wall's structural and physical properties but the environmental benefits also. The results are published in a series of information papers on the BRE bookshop website. Case studies included in the papers demonstrate the material's applications; for example, the Wales Institute for Sustainable Education (WISE) building where the technology was partially used in its construction.

University of Bath testing an earth brick wall's flexural strength.

Photo: Greenspec

International Standards

Currently, the UK has no standards regarding earth brick wall construction; specifiers can only refer to international ones. The range of international standards includes New Zealand's NZS 4297, 4298 and 4299 (1998), Spain's Ministry of Transport and Public Works publications, and New Mexico's Building code. However, the most relevant guidance document to the UK is Germany's unofficial 'Lehmbau Regeln' (The Clay Construction Regulation) published in 1999. Although it is not a DIN standard, it is used as a national reference document that covers:

- General requirements for earthen construction.

- Types of suitable soil and the appropriate selection tests.

- The different construction methods and materials.

- The design procedures for each method.

- The properties of earth (density, sound absorption, etc).

- Some contractual issues.

There are a number of other European organizations that are investing in earth construction research, including France's CRAterre and Germany's Dachverband Lehm.

Environmental impact

A major concern of the construction industry is the huge volume of carbon put into the earth's atmosphere during product manufacture - especially significant when a material uses extreme temperatures in its refinement or extraction.

Earth and fired brick manufacturing processes are similar, but because earth bricks are air dried (sometimes using the exhaust air from brick kilns) they give substantial savings in carbon emissions and embodied energy. To put it into context, in Bath University's 'Inventory of carbon and energy (ICE)', version 2.0, fired bricks have a calculated embodied energy of 3 MJ/kg and unfired bricks 0.45 MJ/kg. Whilst not as structurally strong as fired bricks, earth bricks can be manufactured to take domestic loads up to two storeys, but require an increased wall thickness.

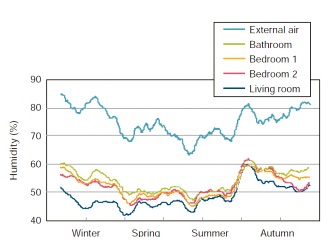

Whilst not consistently recognized for its structural uses, earth is a material known to improve a building's indoor air quality through its hydroscopic properties. Unlike most other masonry construction materials, unfired clay is very vapour permeable and can passively regulate relative humidity levels - maintaining levels of 40-60% and minimizing the risk of mould growth, diseases and allergies.

The inert properties and zero toxicity of non-stabilized earth cause no environmental pollution and are normally harmless to a site's biodiversity. The constituents of earth products are all produced naturally and require only shallow excavation. The remaining shallow pits are either refilled with topsoil or left to flood, returning the site to natural habitation.

During demolition, an earth structure has a number of recycling options. Like steel, earth building materials can be reduced to their raw state and remanufactured into a new product. Unlike steel, they can be used as a fill material that will not pollute the ground.

Relative humidity fluctuations in a bathroom with earth brick walls.

From BRE publication, 'Earth Masonry - Design and construction guidelines'.

Conclusions

Earth brick walls are an excellent example of efficient sustainable construction; when properly designed they can easily be used internally and externally. Construction professionals can design these walls effectively by:

- Uniformly distributing loading.

- Using finishes and insulations that allow the bricks to breathe.

- Protecting the bricks from water penetration.

Although a lack of British standards and the small number of manufacturers of earth bricks limit the product's usage, professionals are recognizing their usefulness in modern construction. With further research and development this natural construction material could replace fired bricks in many constructions, thereby saving valuable energy and resources.